DRIFT: A Floating Pavilion

River Lagan, Belfast

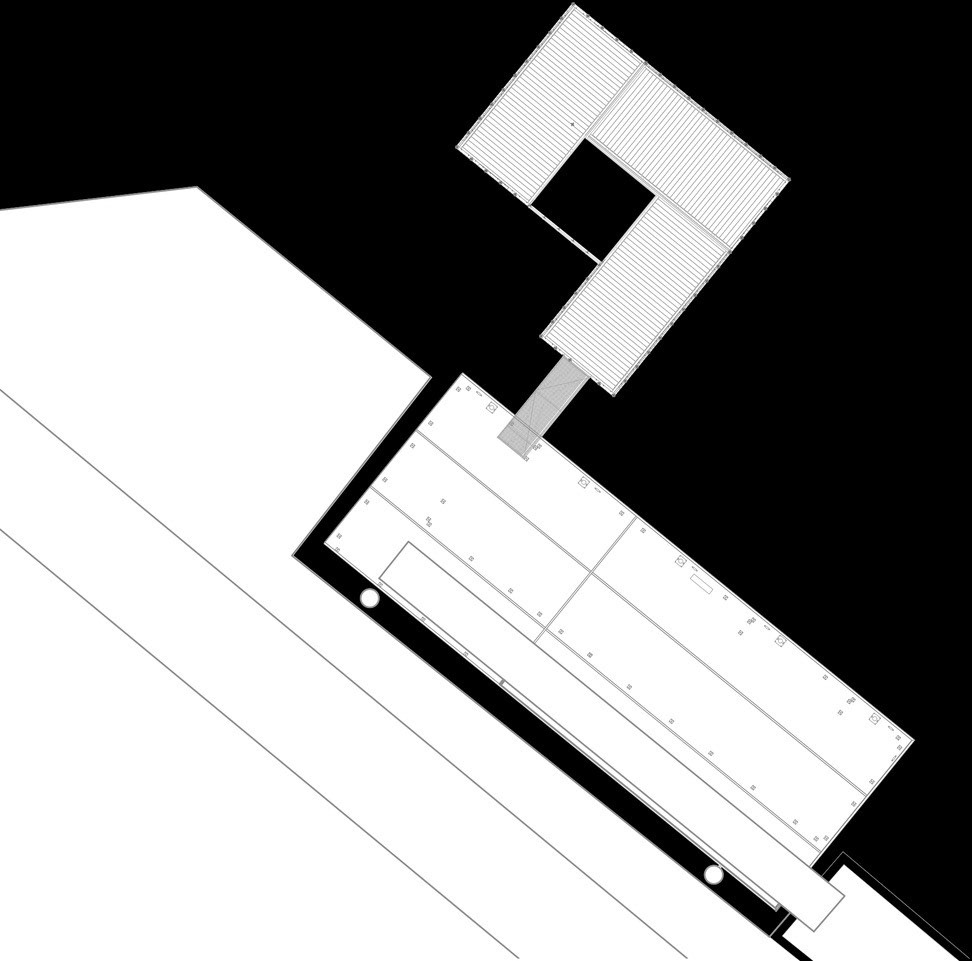

DRIFT is a floating, demountable pavilion designed to create public space on Belfast’s River Lagan as part of the Belfast 2024 programme. Conceived as a shapeshifting structure that adapts to different sites, it invites people to experience the river through sound, movement, and immersion. Developed in collaboration with sound artist Matilde Meireles, DRIFT offered a unique sensory engagement with the water, aiming to strengthen civic connection to an often inaccessible urban river environment. To deliver the project, the team established a dedicated company to take on the roles of designer, contractor, client, and operator — an innovative and hands-on model of project delivery.

Galvanized steel played a critical role in enabling the adaptability, resilience, and longevity of the structure. Working closely with engineers Design ID and Inland and Coastal Marina Systems, the team developed a bespoke galvanized steel edge bracket that enabled the pontoons and scaffold structure to be easily assembled, demounted, and reconfigured in multiple forms. This flexibility was central to DRIFT’s design — allowing it to respond uniquely to each site while ensuring the long-term reuse of components. Galvanizing ensured the structural elements could withstand the challenging riverine environment, reducing maintenance needs and supporting the project's circular, low-carbon ethos.

DRIFT is an exemplar of reusable architecture and place-making in a constrained urban context. The project demonstrates how adaptable design, standardised galvanized components, and cross-disciplinary collaboration can unlock new possibilities for sustainable, public space-making on the water. By combining robust engineering with cultural and ecological sensitivity, DRIFT offers a replicable model for creating flexible, low-impact interventions that foster stronger human and environmental connections in cities.

Detail Coordination: Galvanised Bracket Development and Fabrication

A key structural innovation behind DRIFT’s floating architecture was the design and fabrication of a bespoke galvanised bracket system to connect the floating pontoons with the modular scaffold superstructure. This system was the product of close collaboration between the design team at Design ID, fabricators Inland & Coastal Marina Systems, and the DRIFT design team - OGU Architects + MMAS.

Key Considerations

The bracket system was developed in response to a series of design and fabrication challenges specific to DRIFT’s floating, modular structure. These considerations were integral to the final detail:

• Structural Flexibility: The design had to accommodate various scaffold configurations — supporting one, two, or three poles depending on position — while maintaining a standardised and repeatable bracket detail.

• Ease of Assembly and Reuse: The bracket needed to demount and refix cleanly, allowing for multiple installations and reducing the need for site-specific customisation.

• Corner Integration: Special attention was given to the corner conditions, ensuring the bracket logic remained consistent across linear and orthogonal connections.

• Material Efficiency: The edge support angle was sized for strength, economy, and ease of galvanising — minimising weight and waste without compromising robustness.

• Secure Scaffold Fixing: Scaffold poles had to sit cleanly within the CHS spigots in a way that preserved their structural capacity, without additional fixings or deformation.

• Developing Flexibility: Inland & Coastal’s standard pontoon hole spacing was adapted to DRIFT’s 610–620mm grid through close coordination with the fabricators — ensuring alignment without reengineering the pontoons and allowing the flexibility - we remodelled a standard piece into a beautiful bespoke bit of demountable architecture.

Use of Galvanised Steel in Pontoons: The floating pontoons themselves are fabricated from galvanised steel, providing exceptional durability and corrosion resistance. This material choice not only complements the bracket system but reinforces DRIFT’s commitment to longevity, low maintenance, and circular construction principles.

These technical discussions, carried out between architect, engineer, and fabricator, ensured a bracket system that was robust, demountable, and precise, enabling DRIFT to operate as a sustainable, reconfigurable floating structure.

Bracket Configuration:

• The final bracket detail consists of a galvanised steel angle section with a 33mm diameter CHS (circular hollow section) insert, welded through a CNC-machined hole.

• The CHS was designed to extend through the bottom flange of the angle and sit flush with the top, creating a secure weld interface on the bottom and sides. Fabrication tolerances allowed for a variation up to 160mm overall height, with a 10mm protrusion if preferred by the fabricator.

• An M12 fixing bolt passes through both the bracket and the scaffold pole, with a 14mm diameter hole located 75mm from the base of the scaffold uprights — pre-drilled to ensure on-site consistency.

Engineering Considerations:

• Two final bracket options were reviewed:

o One maintaining a clean flush interface with internal welds.

o A second with a visible CHS protrusion, easing welding access and reducing alignment clashes with the scaffold upright.

• Engineers opted for the latter due to lower site risk and ease of bolt alignment, while fabricators confirmed it could be delivered accurately without compromising weld integrity.

• The use of galvanised steel throughout ensured all elements could withstand exposure to the river’s tidal, corrosive environment, while enabling demountability and reinstallation without degradation.

Manufacture and Precision:

• The brackets were manufactured to exacting standards with CNC hole placement, ensuring precise alignment with standard scaffold components.

• The collaborative design process allowed tolerances to be incorporated into the detail, balancing manufacturing practicality with structural robustness and visual clarity.

This galvanised pontoons and bracket system was a critical enabler of DRIFT’s success — allowing the pavilion to be securely floated, repeatedly disassembled, and reinstalled with minimal intervention. It reflects the project's commitment to durability, circularity, and low-carbon construction, made possible through innovative steelwork detailing and galvanised fabrication.

A key structural innovation behind DRIFT’s floating architecture was the design and fabrication of a bespoke galvanised bracket system to connect the floating pontoons with the modular scaffold superstructure. This system was the product of close collaboration between the design team at Design ID, fabricators Inland & Coastal Marina Systems, and the DRIFT design team - OGU Architects + MMAS.

Key Considerations

The bracket system was developed in response to a series of design and fabrication challenges specific to DRIFT’s floating, modular structure. These considerations were integral to the final detail:

• Structural Flexibility: The design had to accommodate various scaffold configurations — supporting one, two, or three poles depending on position — while maintaining a standardised and repeatable bracket detail.

• Ease of Assembly and Reuse: The bracket needed to demount and refix cleanly, allowing for multiple installations and reducing the need for site-specific customisation.

• Corner Integration: Special attention was given to the corner conditions, ensuring the bracket logic remained consistent across linear and orthogonal connections.

• Material Efficiency: The edge support angle was sized for strength, economy, and ease of galvanising — minimising weight and waste without compromising robustness.

• Secure Scaffold Fixing: Scaffold poles had to sit cleanly within the CHS spigots in a way that preserved their structural capacity, without additional fixings or deformation.

• Developing Flexibility: Inland & Coastal’s standard pontoon hole spacing was adapted to DRIFT’s 610–620mm grid through close coordination with the fabricators — ensuring alignment without reengineering the pontoons and allowing the flexibility - we remodelled a standard piece into a beautiful bespoke bit of demountable architecture.

Use of Galvanised Steel in Pontoons: The floating pontoons themselves are fabricated from galvanised steel, providing exceptional durability and corrosion resistance. This material choice not only complements the bracket system but reinforces DRIFT’s commitment to longevity, low maintenance, and circular construction principles.

These technical discussions, carried out between architect, engineer, and fabricator, ensured a bracket system that was robust, demountable, and precise, enabling DRIFT to operate as a sustainable, reconfigurable floating structure.

Bracket Configuration:

• The final bracket detail consists of a galvanised steel angle section with a 33mm diameter CHS (circular hollow section) insert, welded through a CNC-machined hole.

• The CHS was designed to extend through the bottom flange of the angle and sit flush with the top, creating a secure weld interface on the bottom and sides. Fabrication tolerances allowed for a variation up to 160mm overall height, with a 10mm protrusion if preferred by the fabricator.

• An M12 fixing bolt passes through both the bracket and the scaffold pole, with a 14mm diameter hole located 75mm from the base of the scaffold uprights — pre-drilled to ensure on-site consistency.

Engineering Considerations:

• Two final bracket options were reviewed:

o One maintaining a clean flush interface with internal welds.

o A second with a visible CHS protrusion, easing welding access and reducing alignment clashes with the scaffold upright.

• Engineers opted for the latter due to lower site risk and ease of bolt alignment, while fabricators confirmed it could be delivered accurately without compromising weld integrity.

• The use of galvanised steel throughout ensured all elements could withstand exposure to the river’s tidal, corrosive environment, while enabling demountability and reinstallation without degradation.

Manufacture and Precision:

• The brackets were manufactured to exacting standards with CNC hole placement, ensuring precise alignment with standard scaffold components.

• The collaborative design process allowed tolerances to be incorporated into the detail, balancing manufacturing practicality with structural robustness and visual clarity.

This galvanised pontoons and bracket system was a critical enabler of DRIFT’s success — allowing the pavilion to be securely floated, repeatedly disassembled, and reinstalled with minimal intervention. It reflects the project's commitment to durability, circularity, and low-carbon construction, made possible through innovative steelwork detailing and galvanised fabrication.

Photographs © Joe Laverty / Elyse Kennedy /Dominic Coyle / OGU