© C Wilkinson

© D Lemon

© D Lemon

© D Lemon

© D Lemon

© D Lemon

© Red 7 Marine

© Red 7 Marine

© Red 7 Marine

© Red 7 Marine

© Red 7 Marine

Project Rissa Artificial Nesting Structures

Near shore off Lowestoft

Near shore off Lowestoft

Suffolk

Leading renewable energy company Ørsted are committed to delivering solutions in balance with nature. Through Red 7 Marine, our customer, Four Tees Engineers (FTE) were appointed to work with the assembled collaborative team of partners to develop an industry-first solution, to build three nearshore artificial nesting structures (ANS) specifically designed to house black-legged kittiwake, a vulnerable seabird, off the East Suffolk coastline.

As part of the Development Consent Order from the UK government for Hornsea 3, Ørsted are required to include ecological compensation measures for gull species whose populations could potentially be impacted by the wind farm, in this case the black-legged kittiwake.

Three artificial nesting structures were to be installed about 1 km off the East Suffolk shore, one close to the Minsmere Nature Reserve and the other two located near South Beach, Lowestoft. The offshore location brought with it the many challenges associated with construction and assembly at sea. These included the potential impact of weather and sea conditions, the availability and capacity of specialist seaborne transportation, lifting plant and equipment.

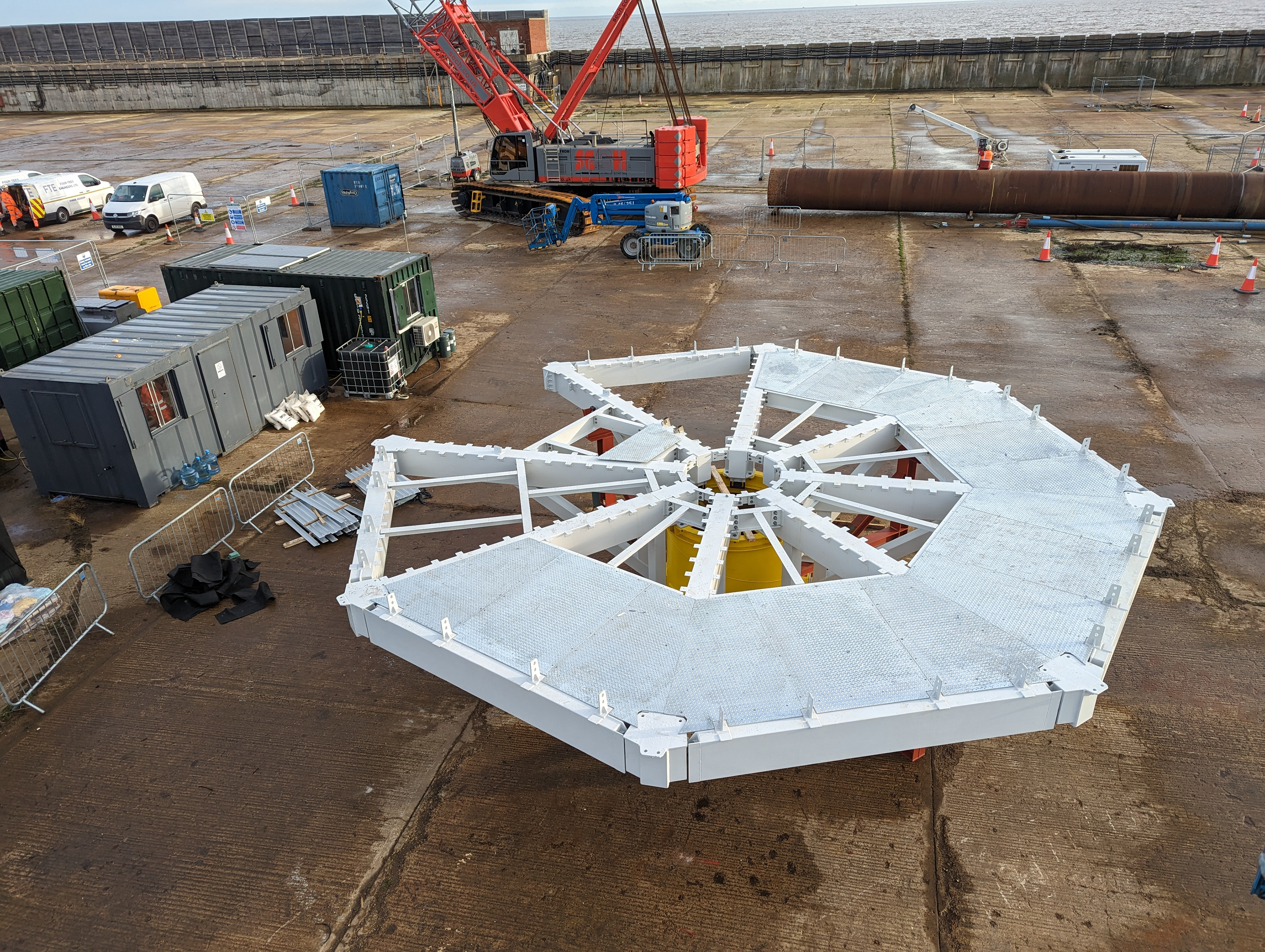

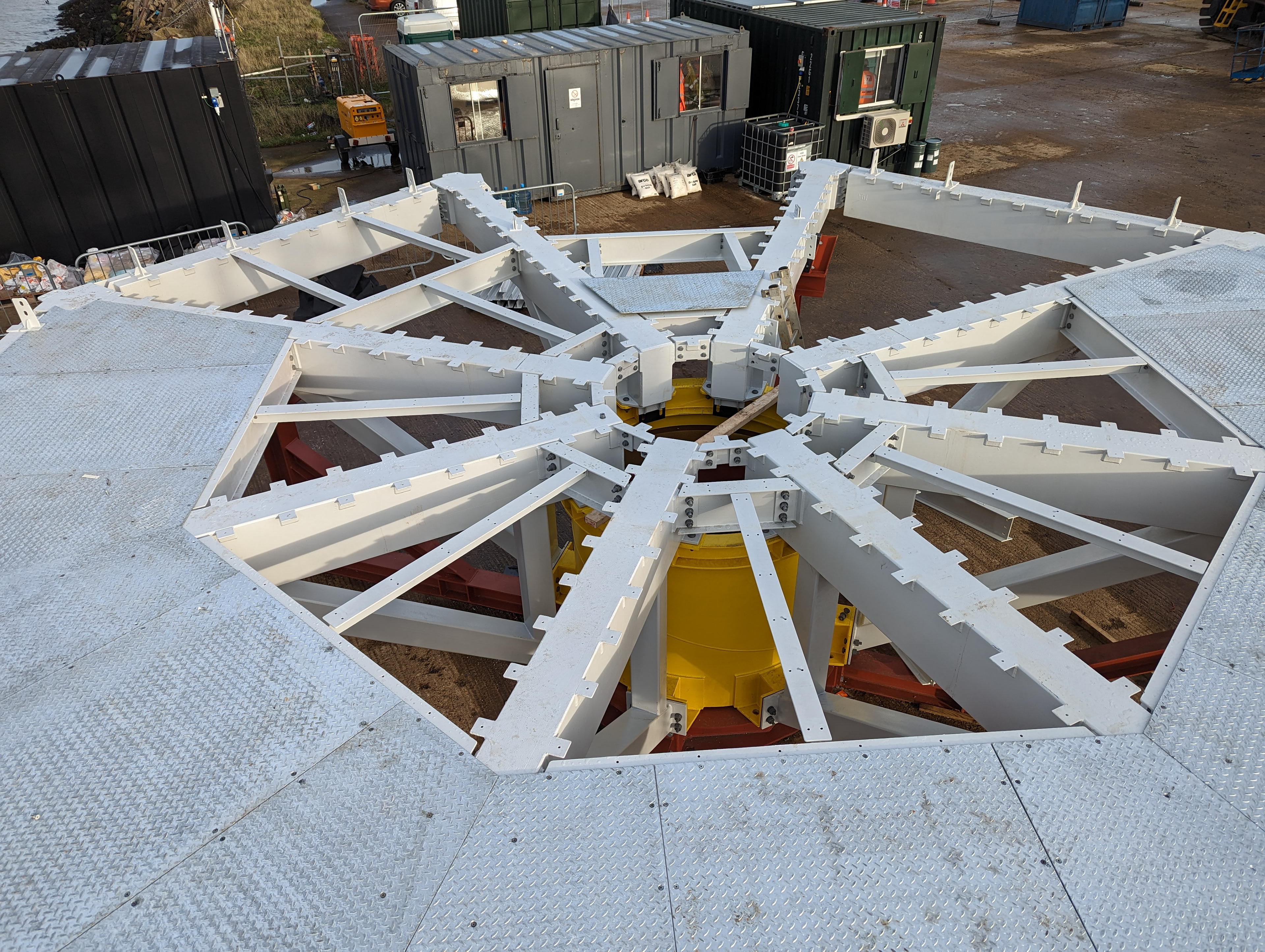

Each ANS is an independent marine structure of considerable size and weight. The octagonal topside structure is 11m wide and 8m tall, weighing 69 tonnes, and is supported above the water on a 1.6m diameter single monopile of 30 tonnes.

The individual nesting structures each have a capacity for around 500 breeding pairs of kittiwakes, nesting in rows of fully partitioned, open and semi-partitioned ledges. The roof pitch and overhang of the topside structure were specifically designed to mitigate avian predators and protect the birds.

Minimising risk of assembly and ongoing maintenance at sea and increasing long term structural resilience.

Knowledge and attention to pre-fabrication detailing and application of galvanising to increase corrosion protective would both minimise the number of “at sea” component assemblies and ensure long term structure resilience and reduce ongoing maintenance in the hostile coastal environment.

The original design was developed around a piecemeal assembly that was to be completed at sea, to a very tight programme. FTE immediately began working with the Ørsted and Red 7 Marine team to fundamentally change the design and installation strategy, taking advantage of FTE’s learning from their previous marine projects that include remote working conditions in Antarctica.

Galvanising was adopted in high wear areas such as floor plates, internal ladders, and internal platforms. Galvanising was selected for these crucial areas of high wear and exposure. Paint systems, if used, would very quickly be eroded by the regular visits from ornithologists resulting in the steel components corroding significantly during use. The top of the floor plates, the internal ladders and platforms will be subject to sea water being brought into the structure on the boots and clothing of people entering the structure from the transfer boats. The external underside surfaces of the structure’s floor plates are also directly exposed significant levels of sea spray on their underside making galvanising essential for the long-term resilience of these ANS Structures.

Photographs © C Wilkinson, D Lemon, Red 7 Marine